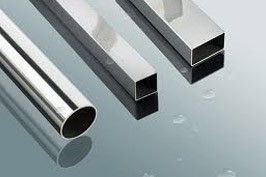

Stainless Steel Tube

|

High corrosion resistance Nickel and chrome are important elements of in stainless steel. The nickel content of SUS304 stainless steel is as high as 8-10.5%; the chromium content reaches 18-20%, 100% up to national standard. The stainless steel property is more stable, and the corrosion-resistance is higher.

High glossiness Special lengthened annealing process is adopted, so the glossiness is higher.

Better stretch bending strength Selects quality raw materials with higher contents of nickel, chrome and copper, etc. so the corrosion-resistance and technological properties are greatly improved. Work hardening is reduced, and deep stamping, bending and such processability under normal temperature is better.

The food hygiene uses the tube Material: 304, 304l, 316,316l. Application: Milk and food industry, pharmaceutical industry, industries with special internal surface requirements. Technological features: Inner wall surface roughness RA exceeds 0.2, with least wall leftovers, easy to clean, preventing bacteria growing. Electropolishing has the function of passivation, inner wall is highly corrosion-resistance. Testing methods: Transverse and longitudinal flattening, reverse flattening, water pressure testing, mechanical property testing, inner surface roughness testing Application: 201 and 202 for lightly polluted environment; 304 for environment with medium pollution; 316 and 316L for heavily polluted environment, coastal environment with salt fog, environment with serious acid rain; 430 for indoor dry environment; 321 for industry applications.

The heat exchanger use the tube Material: 304, 304L, 316, 316L, 210, 202. Application: Heater, boiler, heat exchanger, condensation. Technological features: Inner weld pass leveling, solution, pickling. Performance features: Pipe inner wall is smooth, with low resistance in water delivery, capable of enduring high water current erosion. After solution, weld pass and basic mechanical properties, corrosion-resistance are good, with good performance in deep processing. Testing methods: Transverse and longitudinal Flattening, reverse flattening, water pressure testing, mechanical property testing, hardness testing.

Thin wall stainless steel pipe line Material: 304, 304L, 316, 316L. Application: Mainly used in direct drinking water project and other demanding fluid delivery. Main features: 1. Service life (over 100 years) 2. Low failure rate and leakage rate 3. Quality water delivery, without releasing harmful matter 4. Good water force, no encrustation, smooth, low water resistance 5. High performance-price ratio, hardly needs maintenance in 100-year service life for low cost application 6. Capable of enduring erosion of water current speed of 30m/s or above 7. Exposed laying, elegant look.

Testing methods: Expanding test, flattening test, bending, water pressure(2.45mpa), eddy current testing. Hygienic requirements: Soaking in potassium hypochlorite, potassium permanganate solution. Technological features: Low outside diameter tolerance, easy for grip ring connection. Complete testing equipment ensures 100% leakage-free performance and 100% welding of each pipe and long service life. |

|

|

|

|

|

|

|

|

|

info@taafas.com

info@taafas.com +98 (0) 21 33940731

+98 (0) 21 33940731